回流焊技术资料

回流焊参数技术资料

Lead-free Reflow Soldering Condition

A. 回流焊条件推荐

Recommended Conditions for Reflow Soldering

(1)应采用红外线及热风回流焊接,不宜采用汽相加热回流焊接;

A thermal condition system such as infrared radiation (IR) or hot blast should be adopted, and vapor heat transfer systems (VPS) are not recommended.

(2)推荐回流焊只进行一次,回流焊次数如果需要二次,必须相隔30分钟以上;

Reflow soldering should be performed one time. If the capacitor has to be reflowed twice, 30 minutes must be layout between each time.

(3)无铅回流焊,请符合下述条件:

For lead-free type reflow soldering, please observe proper conditions below:

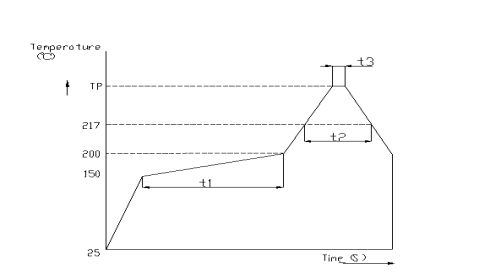

a)从150℃至200℃的预热时间在t1秒钟以内;

The time of preheating from 150°C to 200°C shall be within maximum t1 seconds;

b)电容器顶部温度超过217℃的焊接时间不超过t2秒;

The time of soldering temperature at 217°C measured on capacitors' top shall not exceed t2 (second);

c)电容器顶部尖峰温度不超过Tp℃,在5℃范围内的实际尖峰温度时间不超过t3秒

The peak temperature on capacitors' top shall not exceed Tp(°C), and the time within 5°C of actual peak temperature shall not exceed t3 (second).

B. 回流焊曲线图

Classification Reflow Profile

|

*1. Average ramp-up rate is 3℃/second max. *2. Ramp-down rate is 6℃/second max. *3 .Time from 25℃ to peak temperature is 8 minutes max. |

C. 尖峰温度允许范围

Allowable Range of Peak Temperature

|

Size |

Thickness (mm) |

TP(°C) |

t1(Max,secs) |

t2(Max,secs) |

t3(TP,secs) |

|

Æ4~Æ6.3 |

³2.5 |

260 |

120 |

90 |

5 |

|

Æ8 |

³2.5 |

240 |

100 |

60 |

5 |

|

Æ10 |

³2.5 |

235 |

100 |

40 |

5 |

D. 表面安装推荐尺寸

Recommended Land Size (Unit: mm)

|

Size |

X |

Y |

a |

|

Æ4 |

1.6 |

2.6 |

1.0 |

|

Æ5 |

1.6 |

3.0 |

1.4 |

|

Æ6.3 |

1.6 |

3.5 |

2.1 |

|

Æ8 |

2.5 |

3.5 |

3.0 |

|

Æ10 |

2.5 |

4.0 |

4.0 |